KTI Robotic Arm

-

Scalable & modular

Cost effective

Detects and corrects human-induced errors in loading modules

Future-proofed ability to support future testers

100 module input-output capacity

-

A modular, scalable, and future-proofed ATE solution.

KT-5DA auto

-

128 DUTs simultaneous device testing

7200 MT/s high-frequency testing

2000 UPH, high output

-

Automated DDR5 device tester with:

dynamic parameter adjustment

intelligent classification

post package repair

a curated test algorithm library (+ custom dev. available)

a user-friendly operating system

KT-HC2

An automated, stable heat chamber for use with all KingTiger testers.

-

Screen for potential Early Life Failures (ELF)

Performs dynamic Testing During Burn-In (TDBI)

Elevated temperature Production test capability

Automated temperature test capability

(via monitoring the Event pin)Delayed start testing based on required soak time via the TigerClaw setting interface

DUT characterization of voltage and frequency over temperature

FA / Reliability testing

-

The main purpose of Heat Chamber is to provide a temperature controlled environment for DUT testing. The

Heat Chamber is designed to accelerate and detect Early Life Failures (ELF). Testing During Burn-In (TDBI)

provides dynamic functional tests verifications (generally at reduced speed), which can detect potential

weak cells.The High Temperature Testing System is designed to test DRAM memory modules in high-temperature

conditions. It executes its tests in a cost effective and precise engineering testing environment with the

objective is to simplify the DRAM Failure Analysis process by combining all the steps in ONE.The High Temperature Testing System includes a KTI tester and a Heat Chamber. The Heat Chamber

serves to test memory modules at elevated temperature. It includes the temperature controller, which

provides the controlled environment temperature of the Heat Chamber and sets up the temperature

profiles.The Heat Chamber requires the following operating parameters: Voltage 100 V to 240 V, power

consumption 1,500 W Maximum. It provides DUT testing in the temperature range from 25°C to 85°C.

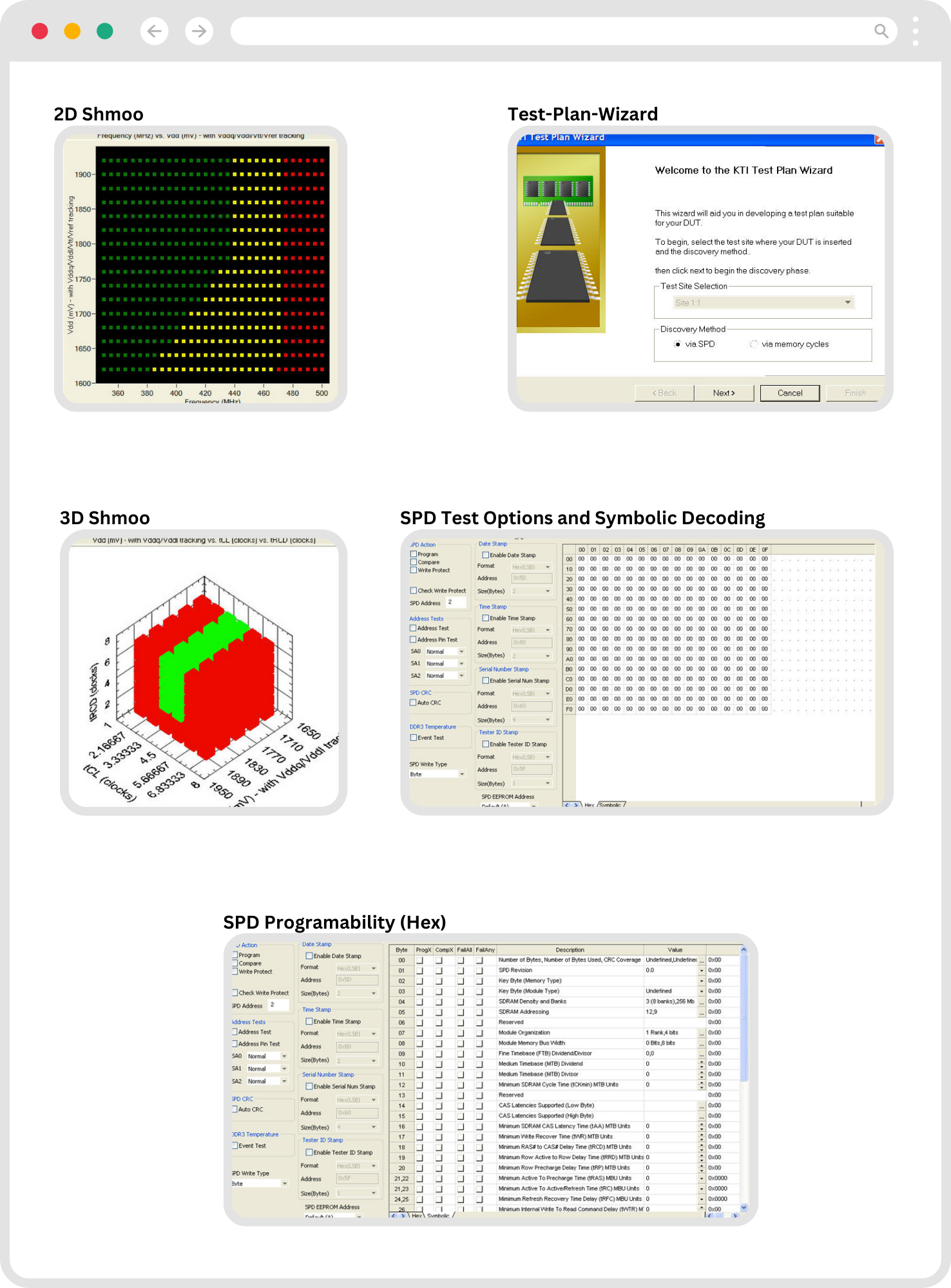

TigerClaw

A state-of-the-art software specifically designed for use with KingTiger’s Testers. TigerClaw gives users an easy-to-use interface, powerful control of the testing configuration, and comprehensive testing result displays.

-

Flexibility and Customizability: TigerClaw allows easy customization of testing routines, with both support for all industry-standard algorithms and custom algorithms.

User-Friendly Interface: Despite its advanced capabilities, Tiger Claw Software is designed to be easy to use, with an intuitive interface that allows operators to manage complex testing procedures with ease

Comprehensive SPD Management: Tiger Claw Software excels in managing thousands of SPD images in various formats, ensuring that your memory modules are correctly programmed and verified. This reduces the risk of errors that could lead to costly returns or field failures.

Advanced Serialization and Tracking: With features like serialization, bar code stamping, and time/date stamping, Tiger Claw Software provides detailed traceability for each memory device tested. This level of tracking ensures that every module meets the highest standards before leaving the production line.

Why Choose Tiger Claw Software?

Tiger Claw Software is a seamless solution for controlling King Tiger Test Systems. It empowers manufacturers to deliver memory modules that meet rigorous quality standards, reducing the likelihood of costly field failures and enhancing customer satisfaction.n text goes here